Engineered for Excellence

We are now offering quick delivery on our PROTEGO® VD/SV's. Available in 2-12" flange sizes and up to 27.7 inW.C. (1psi, 16oz/in2) setting range, in aluminum, carbon steel, and stainless steel to cater to diverse industry needs. Each valve embodies our commitment to quality, durability, and performance. From 1-2 week delivery to unmatched reliability and ease of maintenance, PROTEGO® VD/SV's are your solution for operational challenges in demanding environments. Benefit from our advanced 10% technology that enhances system efficiency and minimizes emissions.

Uphold Industry Standards with Confidence

PROTEGO® VD/SV valves are engineered to meet the stringent requirements of EPA Method 21, ensuring ultra-low emissions and superior performance under any operational conditions. Our commitment to environmental stewardship means you don't just meet regulations — you exceed them.

Designed To Comply With The Rigorous NSPS OOOO Standards

PROTEGO® valves ensure you maintain operational excellence and environmental integrity simultaneously. Navigate compliance with ease, and secure your peace of mind.

Get Detailed Insights – Download Our PROTEGO® OOOO Flyer Now

VD/SV

Pressure and Vacuum Relief Valve

- 10% technology for minimum pressure increase up to full lift

- Extreme tightness, resulting in lowest possible product losses and reduced environmental pollution

- Set pressure close to opening pressure for optimum pressure maintenance in the system

- Very high flow capacity

- Valve pallet is guided inside the housing to protect against harsh weather conditions

- Can be used in explosion hazardous areas

- Automatic condensate drain

- Maintenance-friendly design

- Best technology for API tanks

Function and Description

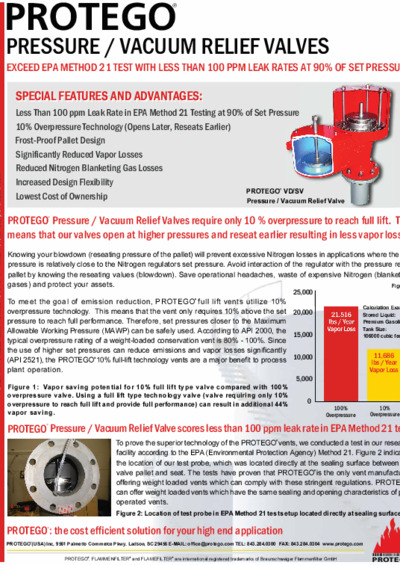

The VD/SV type PROTEGO® valve is a highly developed pressure and vacuum relief valve with excellent flow performance. Typically, the valve is installed on the in-breathing and out-breathing lines of tanks, vessels, and process equipment to protect against unallowable overpressure and underpressure. The valve prevents emission losses almost up to the set pressure and prevents air intake almost up to the set vacuum.

The device will start to open as soon as the set pressure is reached and only requires 10% overpressure to full lift. Continuous investments in and a commitment to research and development have allowed PROTEGO® to develop a low pressure valve which has the same opening characteristic as a high pressure safety relief valve. This “full lift type” technology allows the valve to be set at just 10% below the maximum allowable working pressure or vacuum (MAWP or MAWV) of the tank and still safely vent the required mass flow. The opening characteristic is the same for pressure and vacuum relief.

Due to our highly developed manufacturing technology, the tank pressure is maintained up to set pressure with a tightness that is far superior to the conventional standard. This feature is achieved by valve seats made of high quality stainless steel and with precisely lapped valve pallets or with an air cushion seal in conjunction with high quality FEP diaphragm. After the overpressure is released or the vacuum is balanced, the valve re-seats and provides a tight seal.

The optimized fluid dynamic design of the valve body and valve pallet is a result of many years of research, resulting in a stable operation of the valve pallet, optimized performance, and reduced product losses.

Ready to Optimize Your Systems? Request a Quote Today

Need More Information? Contact Our Valve Experts Now